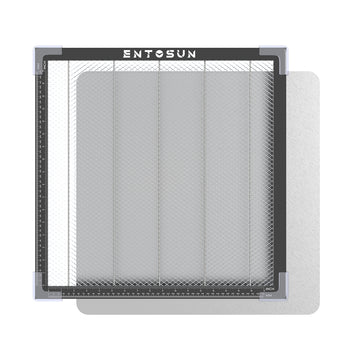

Laser Honeycomb Bed - 15.7 x 15.7 inch

This honeycomb panel kit is made of iron and aluminum, stable, strong, durable and rustproof. Fine workmanship, flat and smooth, with uniform honeycomb holes, promotes smoke evacuation.

Laser Honeycomb Bed - 15.7 x 15.7 inch

- This honeycomb panel kit is made of iron and aluminum, stable, strong, durable and rustproof.

- Fine workmanship, flat and smooth, with uniform honeycomb holes, promotes smoke evacuation, protects wood and other materials from smoke, and enhances your creations.

- It is available in two sizes, which is 15.7*15.7 inches and 19.68*19.68 inches.

- The set of honeycomb panels has four corners to protect you from cuts on the edges.

- In addition, those four corners have a certain height, which makes there a specific height between the honeycomb and the aluminum panels so that when the metal plate at the bottom of the honeycomb panel glows brightly, the laser has penetrated the material.

- Moreover, there are two short magnetic strips and two honeycomb material pins are also included with the package, which will hold easily moved material ideally in place on the honeycomb board and help you make clean and consistent cuts (size: 0.39*11.8 inches, which could be cut freely).

- This product is suitable for most diode laser engraving machines on the market.

How to store laser materials correctly?

The panels should be stored horizontally and flat.

The storage location should be dry and weatherproof (indoor).

Average-temperature rooms without large fluctuations in room temperature and air humidity.

The material should not be exposed to direct sunlight, as the protective film can become porous if too much heat is generated.

Too long storage can have a negative effect on the protective film.

How do I reduce the dust generated during engraving or cutting?

It is recommended to set the parameters to engrave effectively through the color surface while only as little as possible is removed from the core material. Also, using a vacuum table and exhaust system to remove the dust generated effectively.